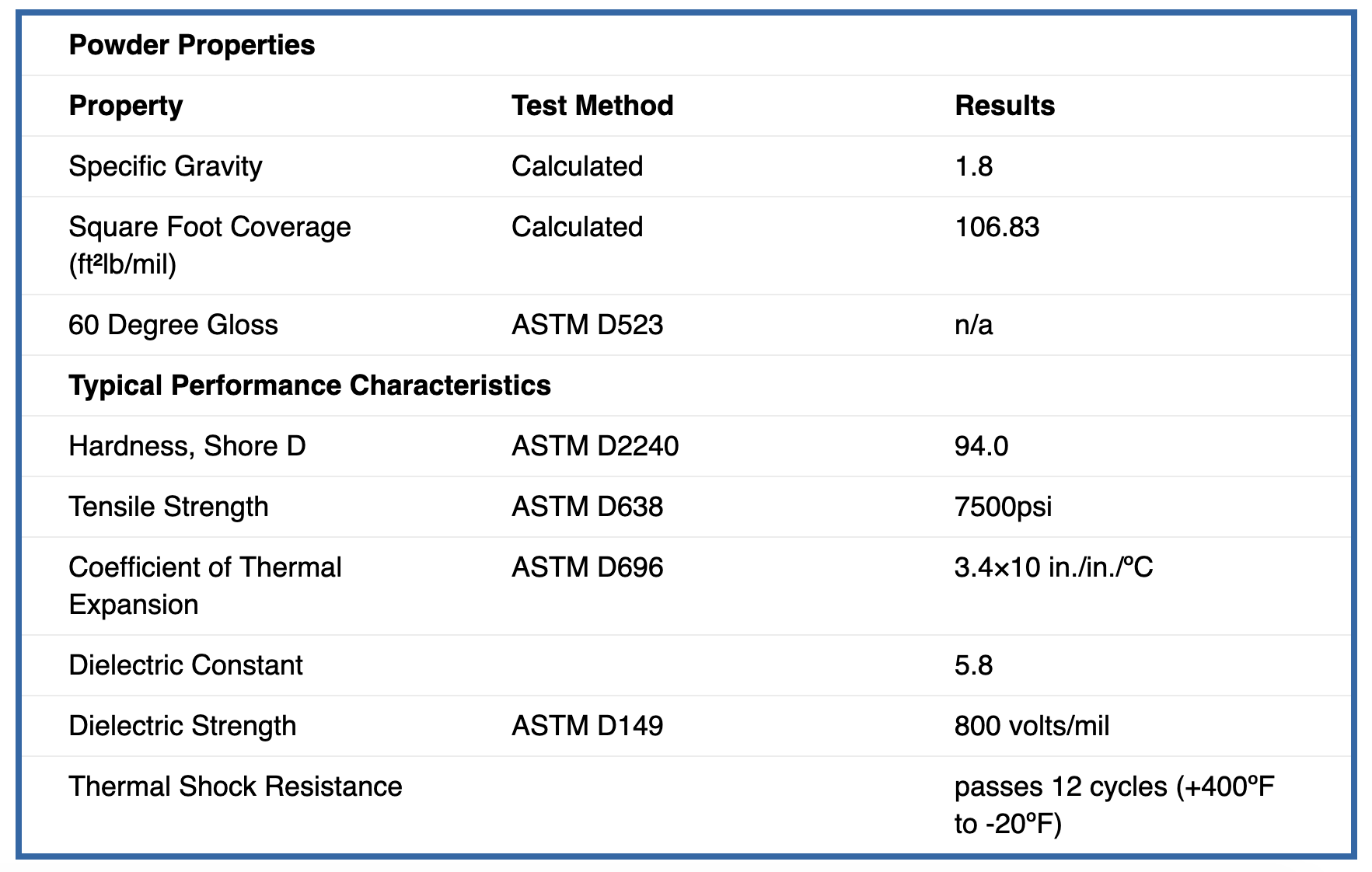

Epoxy is a tough and multi purpose material consisting of the cross linking of an epoxy resin and hardener or co reactant.

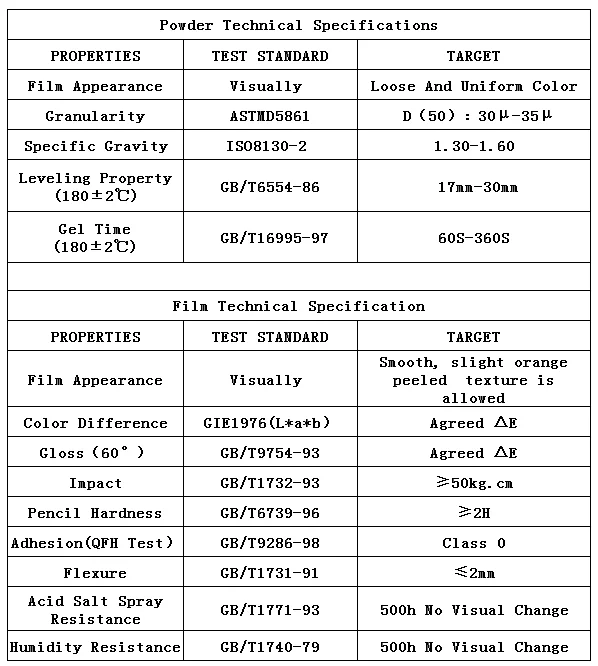

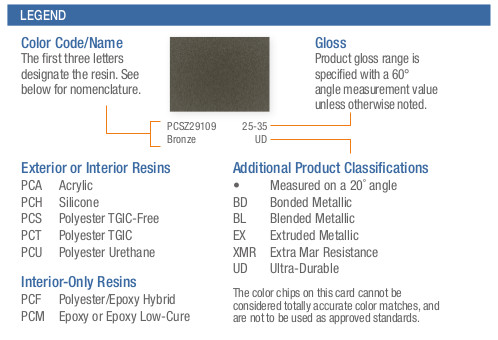

Epoxy polyester powder coating specifications.

Vapour degrease immersion zinc phosphate 1st coat of powder coat zinc rich primer and 2nd coat of nylon modified polyester powder.

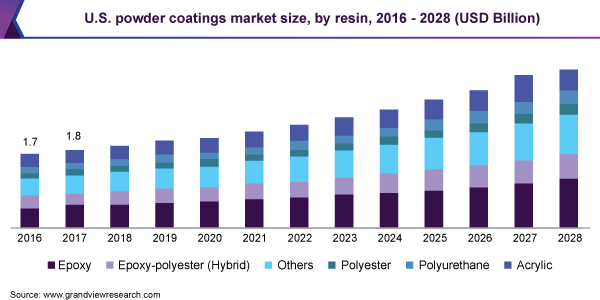

When comparing polyester vs.

The resin and hardener part together is known as the binder.

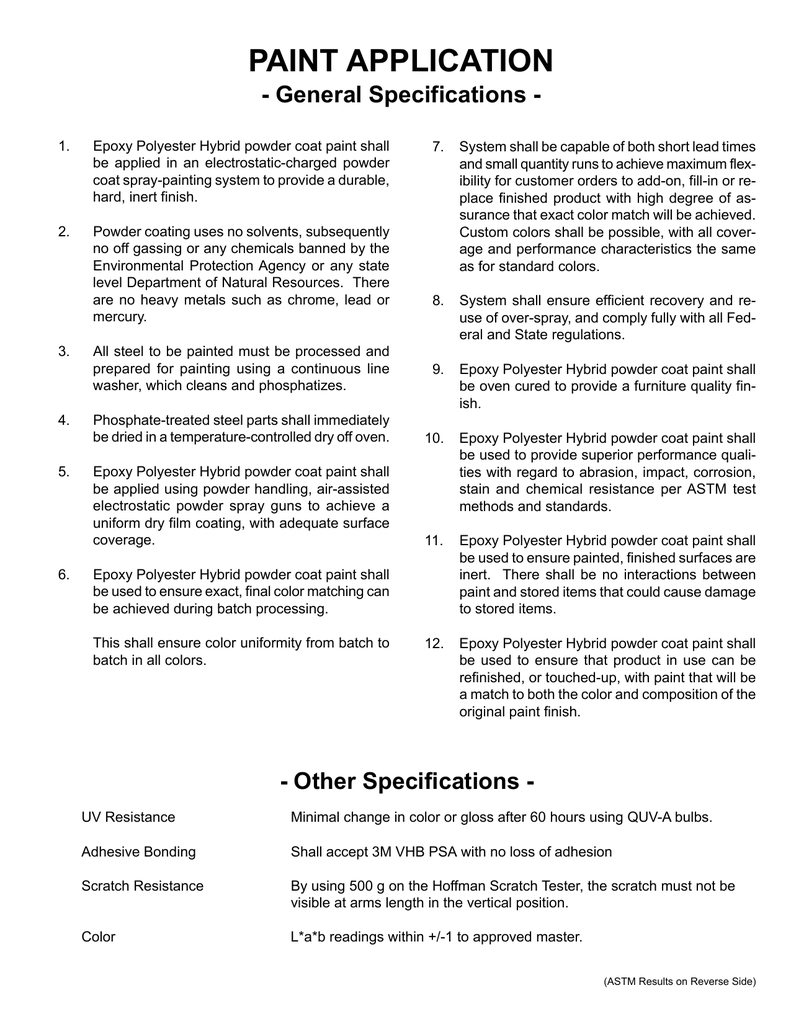

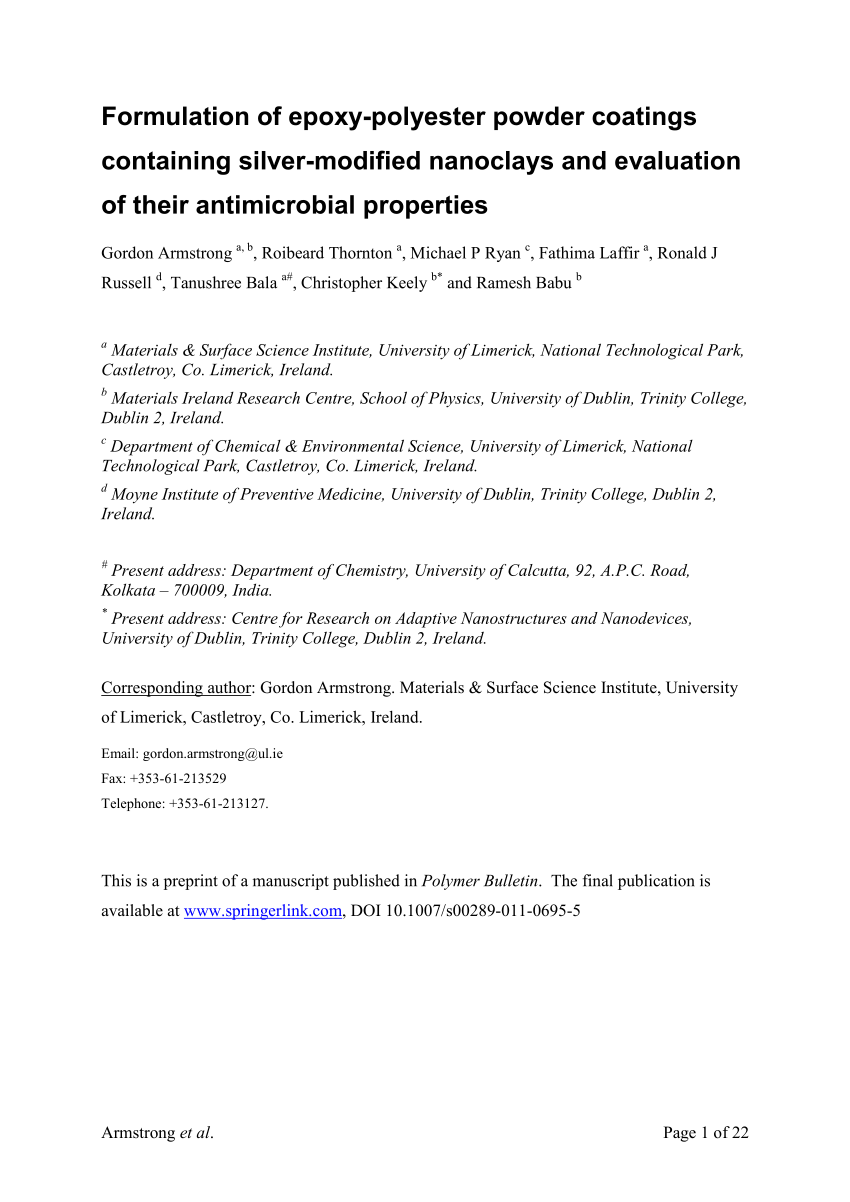

Epoxy polyester powder coatings based on specially selected resins to give the hard durable finish associated with epoxy coating but with superior heat stability and exterior durability.

It is a powder that is easy to use and adheres to metals very well.

This spec will pass over 1000 hours salt spray test and 3h hardness.

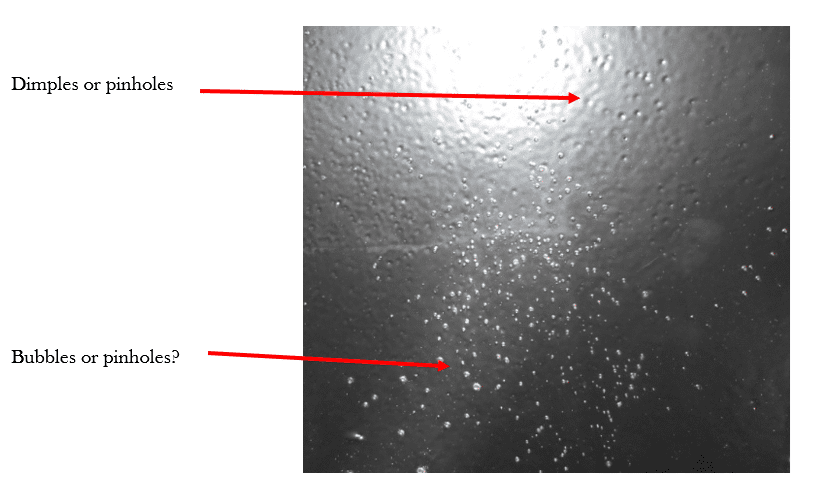

Powder coating also offers a wide range of specialty effects that are hard to achieve through traditional methods.

Tgic polyester powder coating films on the other hand can be applied with greater ease as they can be sprayed at thickness greater than 3 mils 75µm.

Epoxy powder coat one disadvantage of epoxy powders is their inability to weather well.

It has been used in applications involving steel pipeline coating concrete floor paint and even heat shields for space capsules.

Hardener or curing agent.

Tgic polyester powders can also be cured at lower temperatures making them ideal for cast parts and extruded parts.

Typical applications for epoxy polyester powder coatings are those where a tough decorative finish is desirable such as domestic appliances and office furniture.

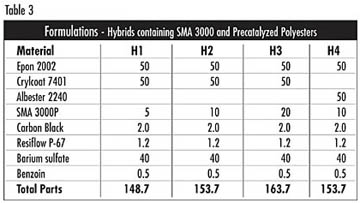

6000 series epoxy polyester hybrid systems these products have a broad formulating range that can meet many decorative and functional application requirements.

Thermaset limited epoxy polyester powder coatings can be applied by manual or automatic electrostatic spray equipment general recommendation is for a film thickness of 60 100 microns depending on covering power and colour with a minimum recommendation of 60 microns.

Excellent adhesion can be obtained through pretreatments of the metal involved including sandblasting and phosphate coating.

Yet they can rapidly lose gloss and begin to chalk when exposed to sunlight making them best suited for interior applications.

This specification covers standard requirements for pipe piles with protective fusion bonded epoxy powder coating applied by the electrostatic spray flocking or fluidized bed process.

As the name indicates in fusion bonded epoxy coatings the resin part is an epoxy type resin.

The list goes on and we could get into better scratch resistance toughness and hardness than traditional liquid paints but let s take a look at some of the different powders used that help achieve these characteristics.