Qualities with a cobalt content of 49 and 2 vanadium are offering in addition low coercivity forces and therefore best possible parameters for highest performance electric.

Electric motor magnetic saturation.

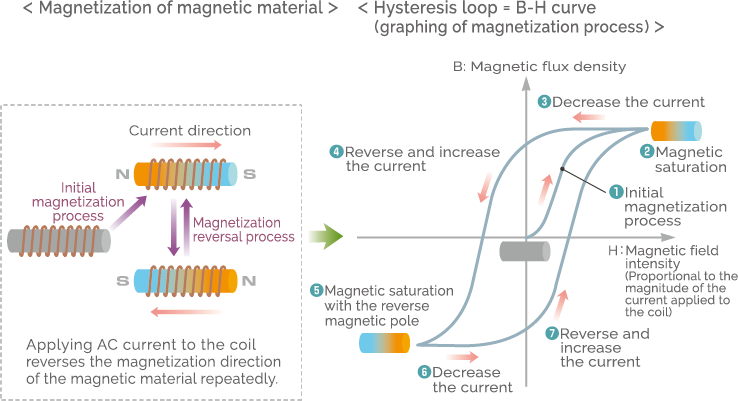

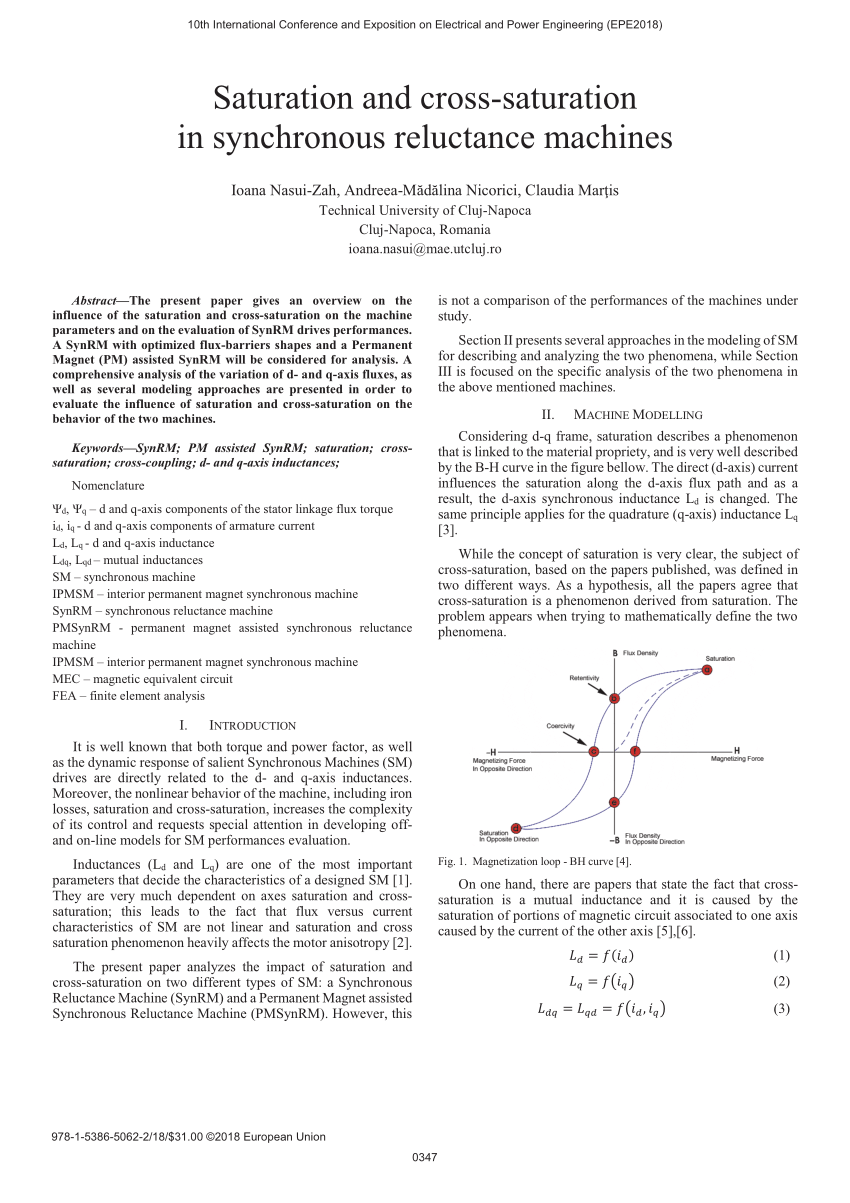

It continues to increase very slowly with the field due to the vacuum permeability saturation is a characteristic of ferromagnetic and ferrimagnetic.

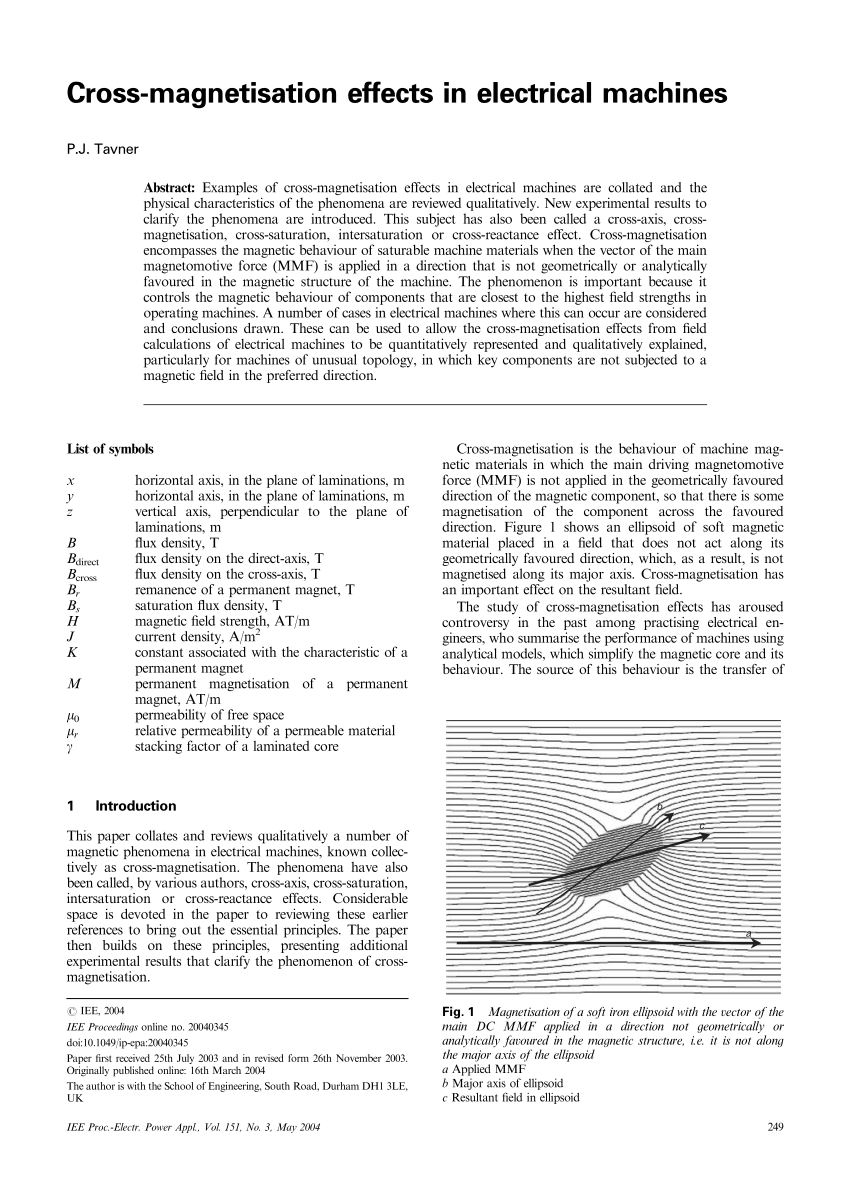

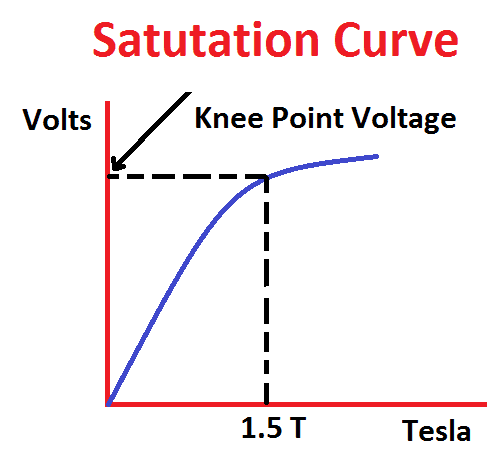

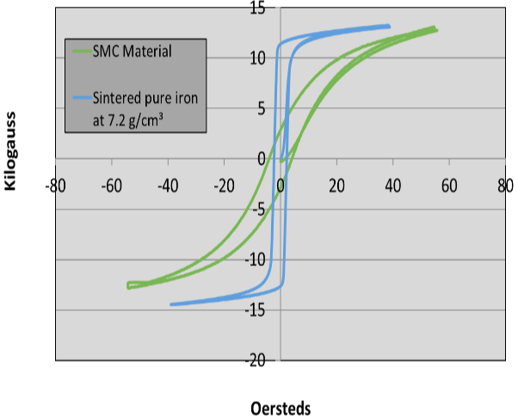

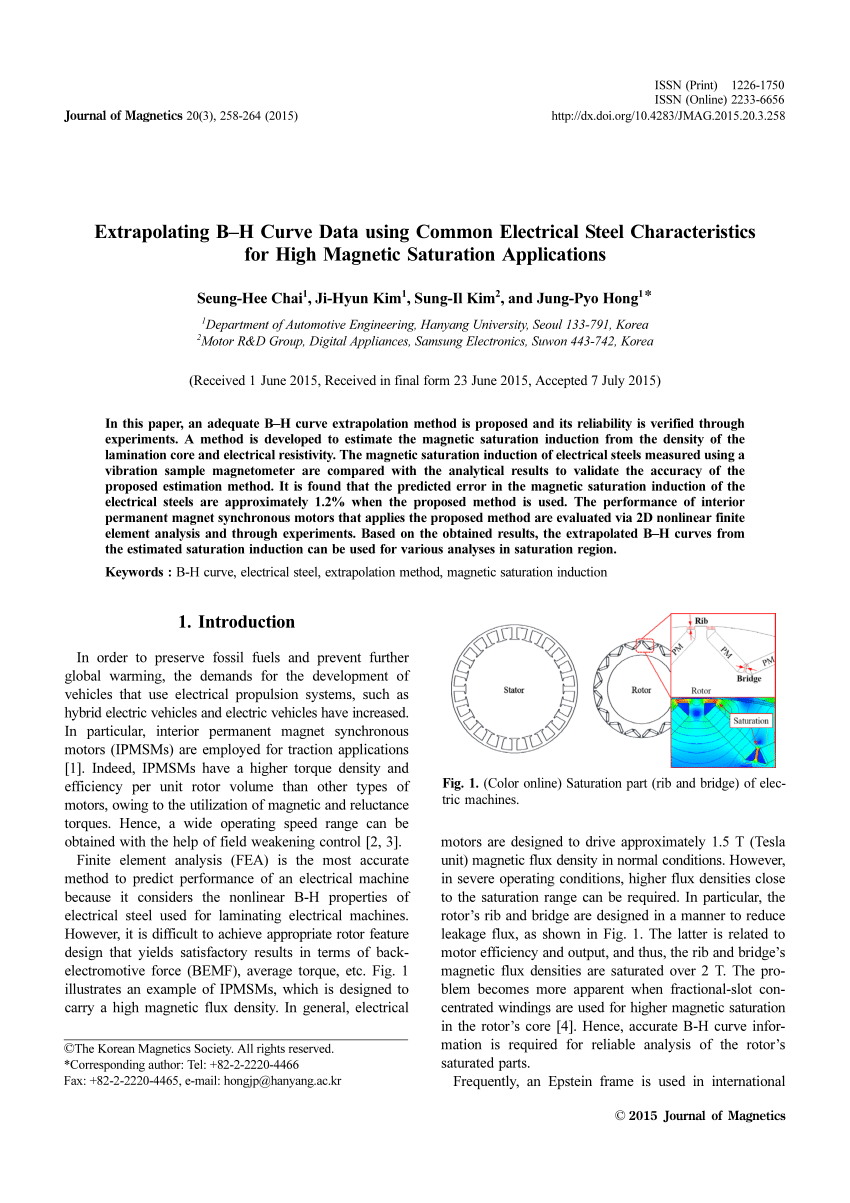

Seen in some magnetic materials saturation is the state reached when an increase in applied external magnetic field h cannot increase the magnetization of the material further so the total magnetic flux density b more or less levels off.

So for the motor design experts is there a point where running to many amperes through a given motor by using to big of a prop will result in the saturation of the magnetic field in the steel poles.

If the frequency related to the rate of change of flux drops the magnetic field must increase to maintain a fixed voltage.

Thanks to their high magnetic saturation of up to 2 4 t the cobalt iron cofe alloys vacoflux and vacodur are generally suitable for all applications where high flux density and minimum weight are required.

Copper losses will increases from the higher current and hysteric iron losses will increase.

Danish scientist hans christian ørsted discovered in 1820 that electric currents create magnetic fields.

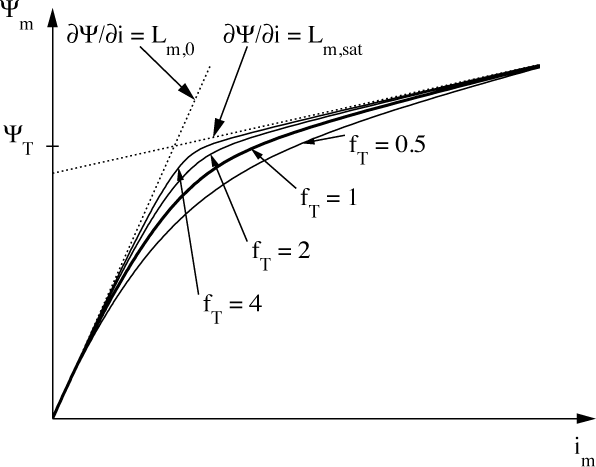

The method is based on assuming an equivalent magnetic circuit and representing the true magnetising characteristic of the iron forming the magnetic circuit by an.

A motor makes torque from the product of it magnetic field strength and electric current.

An analytical method for the calculation of the effect of magnetic saturation on the leakage reactance of three phase induction motors is developed and confirmed by experiment.

This prevents magnetic saturation at which a motor s rotor cannot be magnetized further causing high currents.

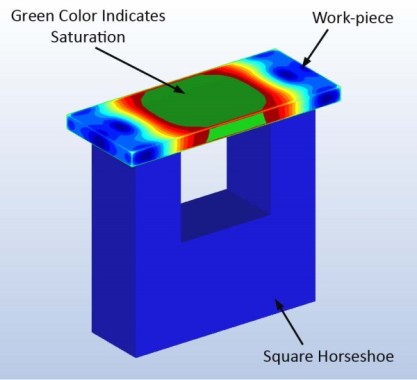

Most machines are designed to run with the magnetic field strength just below saturation.

Or by using to high of a voltage on the motor.

Voltage to be applied is calculated from the applied frequency required to.

An increase of field in the neighbor hood of 10 will cause the core to go into saturation.

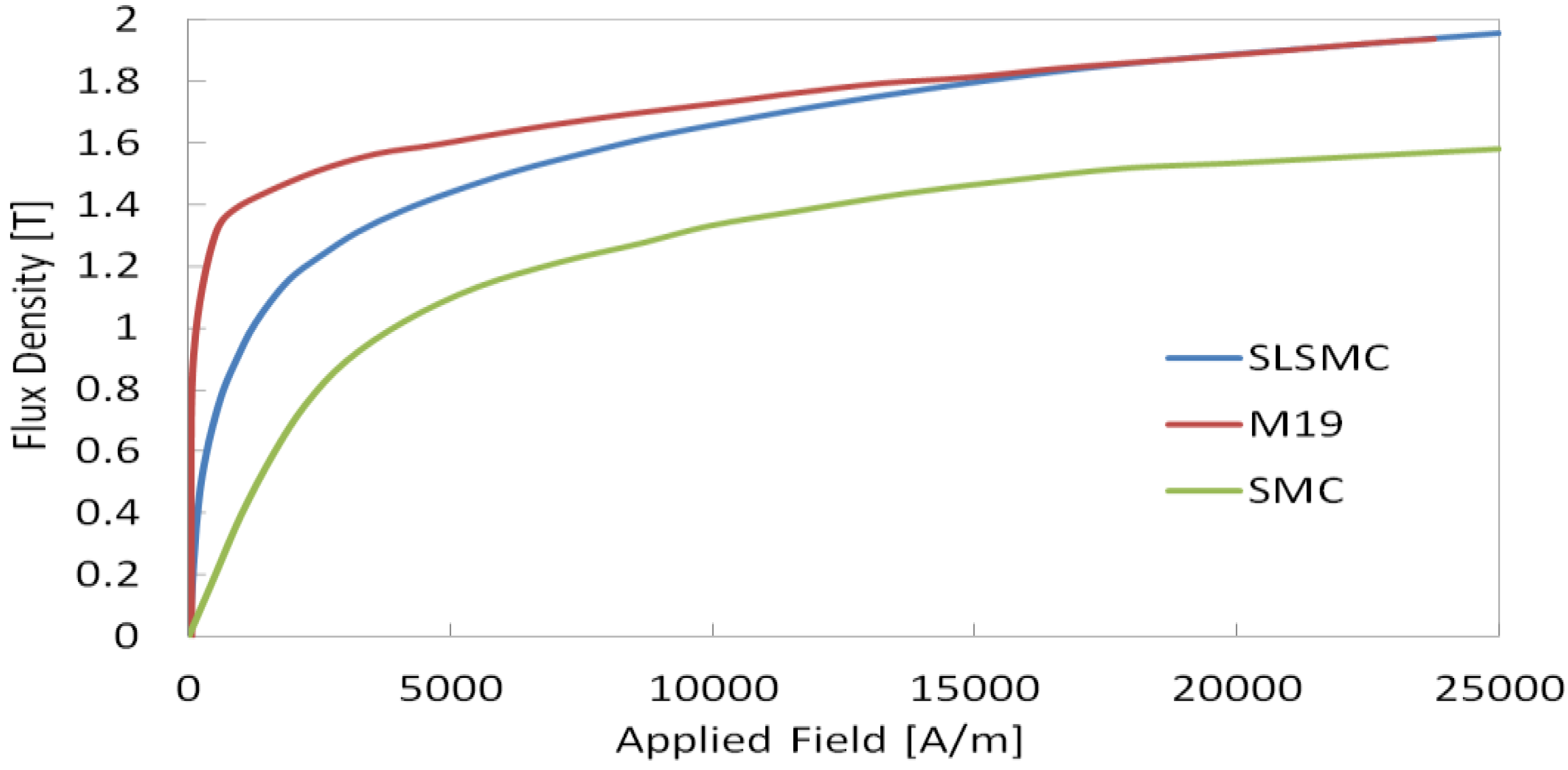

The saturation magnetic density is lower due to the silicon content of the conventional motor core made of non grain oriented ngo silicon steel.

To avoid the undesirable effect of the magnetic saturation the size of the iron core suitably chose for a particular engineering application.

Generally volume of the iron or steel core of magnetic path in a machine is so chosen that flux density of the core does not cross the limit of 1 5 tesla in normal operating conditions.

It is increasingly difficult to meet the demand for high power density and high torque density of modern motors.

Reduction in motor torque per ampere of current supplied.